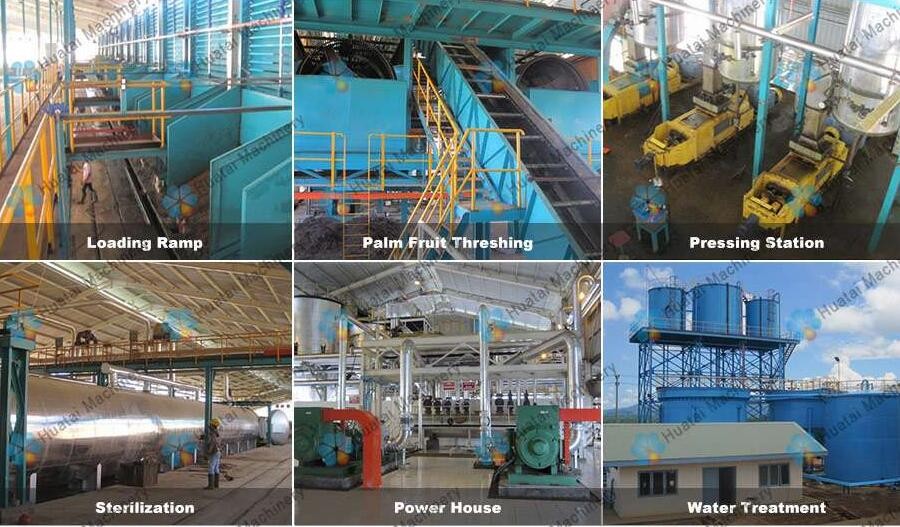

The palm oil press process is divided into five steps:

1. Palm fruit receiving and storage section-palm oil press machine

Ripe fresh palm fruit ears are collected from the orchard and transported by truck to the unloading station. Let the fruit ears fall freely into the fruit cage cart.

2. Sterilization section--palm oil press machine

Sterilization involves steaming the oil palm fruit at high temperature for about 60 minutes in a sterilization equipment to destroy the lipase in the pulp to prevent the free fatty acid content in the oil from increasing. It makes palm fruit be soft and convenient for mechanical threshing, and also facilitates the subsequent shelling of the fruit core and reduces the damage of the kernel.

3. Palm fruit removal section-palm oil press machine

The fruit kernels of oil palm account for about 60% of the entire fruit bunch. The purpose of threshing is to separate the palm fruits from the fruit bunch. The separated palm fruits are discharged into the pressing section.

4. Crushing and pressing section-palm oil press machine

The purpose of mashing and steaming is to tear the fruit skin, separate the pulp from the core and mash the pulp tissue, while heating to soften the pulp and destroy the cell structure of the pulp. The palm fruit then enters the continuous screw oil press for crushing.

5. Crude oil purification section-palm oil press machine

After squeezing, crude palm oil is obtained. The machine-pressed crude oil is diluted with water and then settled and filtered to remove fibrous substances from the palm oil. This is the general process of palm oil press machine.