Palm oil production line includes three sections, palm oil pressing plant, palm oil refinery plant and palm oil fractionation plant. As the manufacturer of the palm oil production line, we can offer the whole line or part of the palm oil production line for 5-120TPH with turnkey services.

The introduction of the palm oil production line

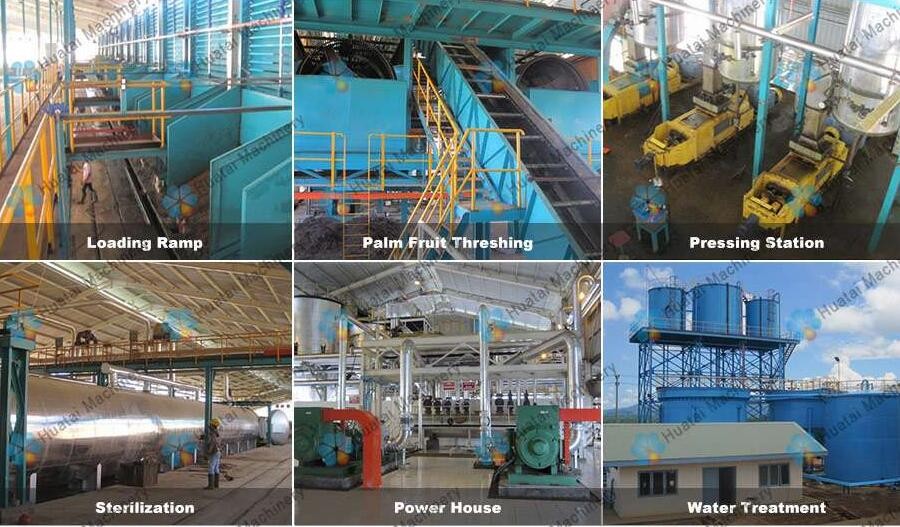

FFB Reception→Sterilizing→Threshing→Digesting→Pressing→Clarifying & Drying

Step 1: Fresh Palm Fruit Reception

Collecting the ripe fresh oil palm fruit bunches from the plantation and transported by trucks, then pour the FFB into the loading ramp after weighed by weighbridge.

Step 2: Sterilizing

The palm bunches are fed through a screw conveyor into the sterilizer where they are steamed at high temperature to break the enzymes in fruit, and to avoid the increasing of the FFA content. On the other hand, the high temperature makes the fruit soften, it is easy for threshing.

Step 3: Threshing

After sterilizing, the prepared palm fruit bunches will be sent into the drum type thresher. It can easily separate the fruit and bunches during rotating process.

Step 4: Digesting

In digesting process, the palm pulp and nut will be separated, and the palm fruit will be crushed, even be destroyed its tissue.

Step 5: Pressing

After digesting, the palm fruit is pressed in the palm oil double screw press. It can yields two components: a mixture of oil, water and solid impurities and a press cake (a mixture of fibre and kernels).

Step 6: Clarifying & Drying

The clarification equipment separates the crude palm oil from the mixture of oil, water and solid impurities and removes other impurities. After clarification, use oil drying system to dry the crude palm oil and pumped it into storage tanks.

Palm Oil Refinery Plant

Main Steps of palm oil refinery:

1. Degumming

In this step gums in crude oil are removed by hydration with the help of phosphoric acid. Degumming is the first step for the whole palm oil refinery process.

2. Neutralization

In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap. Neutralization is also called deacidification, it is the important part for palm oil refinery.

3. Bleaching

During bleaching, unwanted pigments are adsorbed physically and oil will become much clearer. Bleaching is also decolorization in palm oil refinery.

4. Deodorization

Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure. Deodorization is mainly for making oil color lighter during palm oil refinery process. Which can make oil looks good.